Due to rising concerns about environmental waste, the packaging machinery industry is facing significant pressure to use more sustainable materials with tamper-proof designs. Packaging automation can address these challenges while improving operational precision, efficiency, and safety.

Advance Electrical & Automation is dedicated to creating custom automation solutions for industrial packaging machinery. We can help you improve the sustainability and security of your shipping materials using our sophisticated line of sensors, control devices, and data-processing technologies.

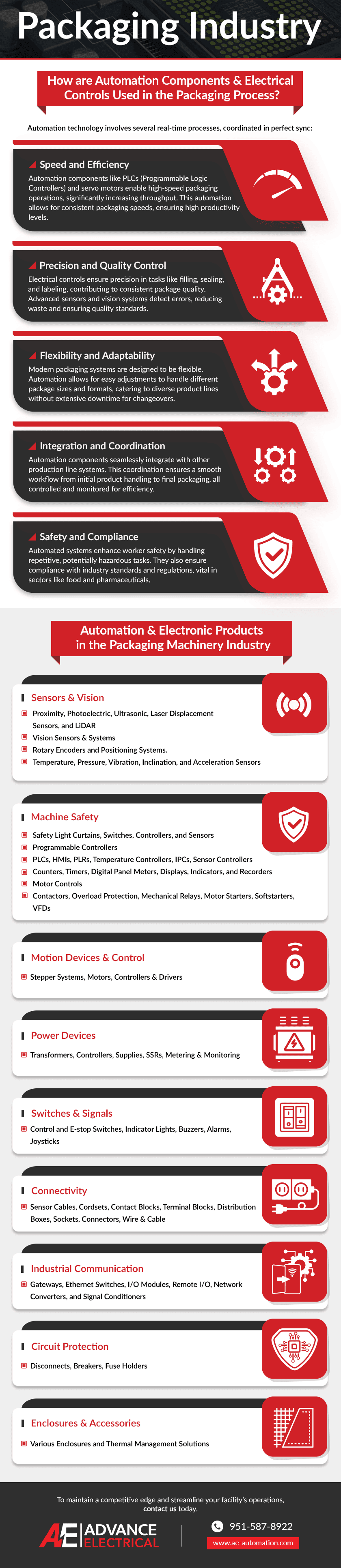

How are Automation Components & Electrical Controls Used in the Packaging Process?

Automation technology involves several real-time processes, coordinated in perfect sync:

- Speed and Efficiency: Automation components like PLCs (Programmable Logic Controllers) and servo motors enable high-speed packaging operations, significantly increasing throughput. This automation allows for consistent packaging speeds, ensuring high productivity levels.

- Precision and Quality Control: Electrical controls ensure precision in tasks like filling, sealing, and labeling, contributing to consistent package quality. Advanced sensors and vision systems detect errors, reducing waste and ensuring quality standards.

- Flexibility and Adaptability: Modern packaging systems are designed to be flexible. Automation allows for easy adjustments to handle different package sizes and formats, catering to diverse product lines without extensive downtime for changeovers.

- Integration and Coordination: Automation components seamlessly integrate with other production line systems. This coordination ensures a smooth workflow from initial product handling to final packaging, all controlled and monitored for efficiency.

- Safety and Compliance: Automated systems enhance worker safety by handling repetitive, potentially hazardous tasks. They also ensure compliance with industry standards and regulations, vital in sectors like food and pharmaceuticals.

Automation & Electronic Products in the Packaging Machinery Industry

Here’s an overview of the automated packaging machinery components from Advance Electrical & Automation.

Sensors & Vision

Proximity, Photoelectric, Ultrasonic, Laser Displacement Sensors, and LiDAR: These sensors detect the presence, distance, and characteristics of objects, crucial for precise packaging operations.

Vision Sensors & Systems: Essential for quality control, these systems inspect and verify product labeling and packaging integrity.

Rotary Encoders and Positioning Systems: They provide precise positioning and speed control, critical in packaging processes like labeling and filling.

Temperature, Pressure, Vibration, Inclination, and Acceleration Sensors: These monitor machine conditions, ensuring optimal performance and preventing malfunctions.

Limit Switches: Used for detecting the presence or position of objects, aiding in automation and safety.

Machine Safety

Safety Light Curtains, Switches, Controllers, and Sensors: These components ensure safe operation of packaging machinery, protecting operators from potential hazards.

Programmable Controllers

PLCs, HMIs, PLRs, Temperature Controllers, IPCs, Sensor Controllers: These devices control and monitor various functions of packaging machines, ensuring efficient and customizable operations.

Counters, Timers, Digital Panel Meters, Displays, Indicators, and Recorders: Provide real-time data and control for precise packaging processes.

Motor Controls

Contactors, Overload Protection, Mechanical Relays, Motor Starters, Softstarters, VFDs: These components regulate and protect motors, vital for the smooth operation of packaging machines.

Motion Devices & Control

Stepper Systems, Motors, Controllers & Drivers: These ensure accurate and controlled movement, crucial for tasks like conveyor operation and material handling in packaging.

Power Devices

Transformers, Controllers, Supplies, SSRs, Metering & Monitoring: These devices provide and manage power, ensuring reliable and efficient operation of packaging equipment.

Switches & Signals

Control and E-stop Switches, Indicator Lights, Buzzers, Alarms, Joysticks: Enhance the user interface and safety features of packaging machines.

Connectivity

Sensor Cables, Cordsets, Contact Blocks, Terminal Blocks, Distribution Boxes, Sockets, Connectors, Wire & Cable: Essential for integrating various components and ensuring reliable signal and power transmission within packaging machines.

Industrial Communication

Gateways, Ethernet Switches, I/O Modules, Remote I/O, Network Converters, and Signal Conditioners: Facilitate communication between different parts of the packaging system, ensuring coordinated and efficient operation.

Circuit Protection

Disconnects, Breakers, Fuse Holders: Protect electrical circuits in packaging machinery, preventing damage due to overloads or short circuits.

Enclosures & Accessories

Various Enclosures and Thermal Management Solutions: House and protect electronic components, ensuring longevity and reliability,

Take the Next Step in Revolutionizing Your Packaging Operations with Advance Electrical & Automation

Automation is quickly becoming an essential part of production facilities in every industry. In the packaging machinery industry, in particular, automation will help companies reduce waste and improve efficiency, both of which contribute to long-term environmental sustainability. To maintain a competitive edge and streamline your facility’s operations, contact us today.